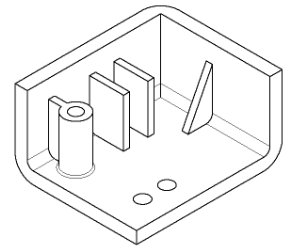

Design guidelines for injection moulded thermoplastics

When designing plastic parts for injection moulding, manufacturing process is one of the most important considerations because part should come out of mould as expected by us.

In injection moulding process, plastic granules are heated to a molten state, injected in the cavity, it is allowed to cool and solidify and forced out of the mould.

In this guide, you will learn various guidelines to be followed regarding wall thickness, ribs, radii and draft etc.